How to Optimize LCD Display Performance in Harsh Environments

In today's rapidly evolving technology landscape, liquid crystal displays (LCDs) are widely used across industries such as automotive, industrial automation, medical devices, and outdoor signage. However, their performance can be severely affected by harsh environmental conditions—including extreme temperatures, humidity, UV exposure, and mechanical stress. To ensure long-term reliability and consistent image quality, manufacturers must adopt a systematic approach to optimizing LCD performance under adverse conditions.

First, selecting the right LCD panel type is critical. For example, high-temperature resistant panels with wide operating temperature ranges (from -30°C to +75°C) are essential for applications in automotive dashboards or military equipment. According to a 2023 report from Display Supply Chain Consultants (DSCC), over 60% of industrial-grade LCDs now feature enhanced thermal stability due to advancements in glass substrate and pixel structure design.

Second, backlighting technology must be adapted for durability. LED-based backlights offer better energy efficiency and longer lifespan than older CCFL systems. In high-humidity environments, sealing the backlight module with IP65-rated enclosures prevents moisture ingress—a key factor in preventing display degradation. Industry data shows that sealed LED-backlit displays have a Mean Time Between Failures (MTBF) exceeding 100,000 hours in field tests conducted by LG Display and BOE.

Third, protective coatings and polarizer enhancements improve resistance to UV radiation and abrasion. Anti-reflective (AR) coatings reduce glare while maintaining visibility in bright sunlight—critical for outdoor kiosks and construction site monitors. A study published in the Journal of Display Technology (IEEE, 2022) demonstrated that multi-layer AR coatings increase contrast ratio by up to 40% under direct sunlight compared to uncoated panels.

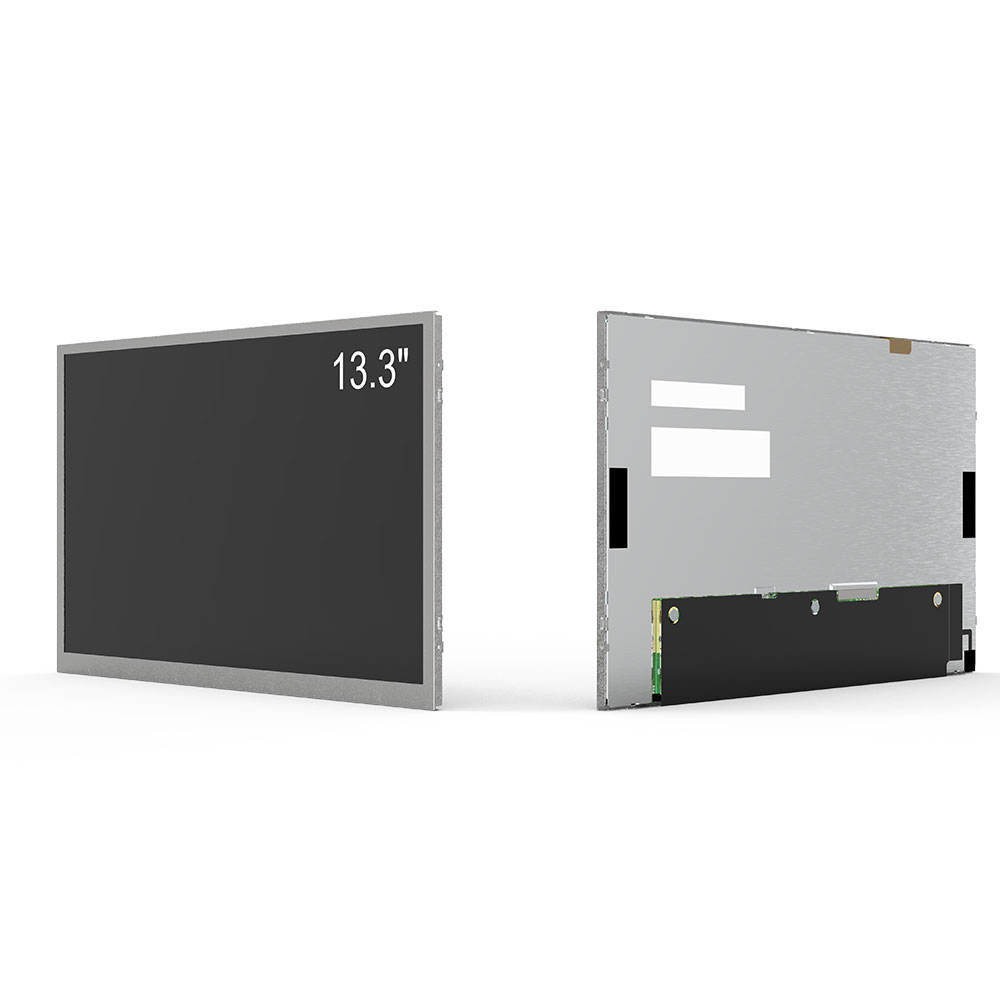

Fourth, mechanical robustness matters. Using reinforced bezels, shock-absorbing mounts, and flexible printed circuits (FPCs) enhances resistance to vibration and impact. This is particularly important in transportation and aerospace applications where displays face constant mechanical stress.

Finally, rigorous environmental testing—such as IEC 60068-2 standards for temperature cycling, humidity, and salt spray—is essential before deployment. Manufacturers like Sharp and Innolux have implemented automated test benches that simulate real-world conditions, reducing field failure rates by over 35% in pilot programs.

By integrating these strategies—panel selection, backlight optimization, protective layers, mechanical reinforcement, and comprehensive testing—engineers can ensure LCDs perform reliably even in the most demanding environments. These practices align with ISO 9001 and IEC 60068 standards, making them both technically sound and compliant with global quality benchmarks.

上一篇:How to Optimize LCD Manufacturing for Higher Yield and Reliability

下一篇:Enhancing Urban Engagement with Outdoor Digital Signage in Orlando